You can contact us 24/7 +1(239) 355-5809

Why the BV89OEP-45 2-Way Butterfly Valve is Most Suitable for Industrial Application

In industrial flow control’s high-stress environment, the selection of valve technology can mean all the difference when it comes to operational efficiency, maintenance cost, and system reliability. Of the numerous possibilities open to engineers and plant managers, the BV89OEP-45 2-Way Butterfly Valve has emerged as a top choice among diversified industrial processes. With its advanced valve design combining rugged construction with versatile function, it can be a top choice for industrial processes with high-stress demands.

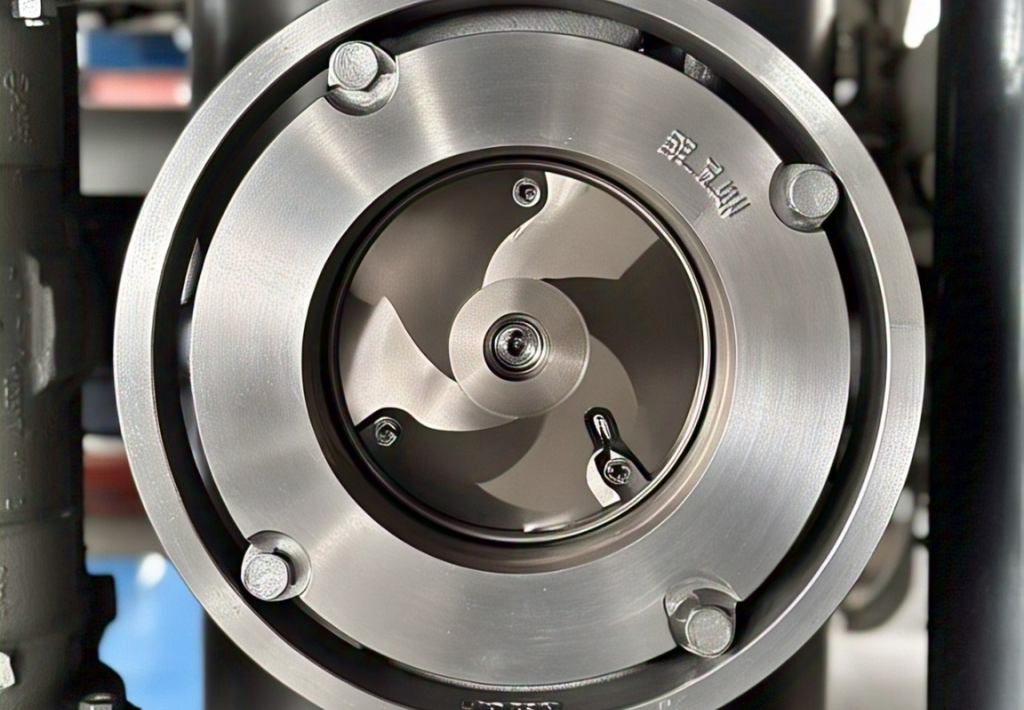

Learning About the BV89OEP-45 Design

The BV89OEP-45 2-Way Butterfly Valve is a result of the implementation of advanced engineering principles on traditional butterfly valve technology. Different from common butterfly valves, the product includes several distinctive aspects making it more suitable for industrial use:

Key Design Features

- Eccentric Disc Design: The “OEP” in the model name signifies its “Offset Eccentric Pivot” design. This design allows the disc to completely disengage from the seat under operation, significantly reducing friction and wear and providing bubble-tight shutoff performance.

- 45-Series Pressure Rating: The “45” designation indicates this valve’s pressure class, with a working pressure rating of up to 45 bar (652 psi), ideally suited for medium to high-pressure industrial processes.

- Dual-Directional Flow Capability: Unlike some butterfly valves that are best operated in one direction only, the BV89OEP-45 provides consistent performance regardless of flow direction.

- Heavy-Duty Stem Construction: The valve boasts a blow-out proof stem construction with heavy bearings, ensuring smooth operation under adverse conditions.

- Advanced Seating System: The seat system consists of high-performance polymer materials reinforced with metal inserts, providing excellent chemical resistance and temperature stability.

Industrial Applications Where the BV89OEP-45 Excels

The BV89OEP-45’s versatility makes it an excellent solution in numerous industrial applications:

Chemical Processing

In chemical processing facilities, valves must withstand corrosive media, fluctuating temperatures, and leak-tight sealing to prevent unsafe releases. The BV89OEP-45’s rugged design and advanced sealing technology position it ideally for:

- Batch process isolation

- Chemical transfer lines

- Aggressive slurry service

- Neutralization systems

The valve’s array of corrosion-resistant materials and specialty coatings provide extended service life even when handling problematic chemical compounds.

Water and Wastewater Treatment

Municipal and industrial water treatment operations benefit from the dependability of the BV89OEP-45 in both clean and fouled water service applications:

- Primary distribution mains

- Backwash systems

- Sludge management

- Chemical injection isolation

Low-torque operation and fine throttling capability of the valve make it particularly well suited to filter backwash systems where flow control must be accurate.

Power Generation

Power plants require valves that can provide the same performance during harsh operating conditions. The BV89OEP-45 performs critical functions in:

- Cooling water systems

- Slurry ash handling lines

- Demineralized water treatment

- Condensate return systems

Its fire-safe features and high temperature resistance make the valve suitable for conventional and nuclear power applications that demand security to be the priority.

Oil and Gas Processing

In harsh environments of refinery and petrochemical plants, BV89OEP-45 works reliably in:

- Product transfer lines

- Tank farm operation involving

- Vapor recovery systems

- Secondary containment applications

Supplied with NACE-compatible materials and construction, these valves can operate in the sour gas and hydrogen sulfide environments common to petroleum processing.

Pulp and Paper Production

The pulp and paper industry is especially demanding with abrasive slurries and caustic chemicals. The BV89OEP-45 performs well in:

- Stock preparation lines

- Bleaching operations

- Black liquor systems

- White water applications

The valve’s abrasion-resistant options and replaceable seat design significantly extend service life in these demanding applications.

Technical Advantages That Improve Performance

Improved Flow Characteristics

The aerodynamic disc shape of the BV89OEP-45 design produces several flow-related benefits:

- Lower pressure drop compared to conventional butterfly valves

- Reduced turbulence and resulting noise

- Less likelihood of cavitation

- Closely controlled throttling over the full operating range

These flow characteristics equate to energy conservation in saving pumping effort and enhancing process control.

Actuation Capability in Any Environment

The BV89OEP-45 accommodates several actuation choices to satisfy specific operating conditions:

- Gear operators for low-frequency applications

- Pneumatic actuators for remote operation in hazardous environments

- Electric actuators for use with automated control systems

- Hydraulic actuators for heavy-torque applications

This flexibility makes it easy to integrate into existing control structures and provide future system expansion options.

Maintenance-Friendly Design

Industrial facilities value equipment minimizing downtime for maintenance. The BV89OEP-45 has some design features that facilitate ease of maintenance:

- Replaceable seats without removing valve bodies from the line

- Adjustable packing externally without shutdown of the system

- Self-lubricating bearings that remove the periodic need for lubrication

- Visual position indicators to facilitate quick confirmation of operational status

Such design options significantly reduce overall cost of ownership and improve operational availability.

Safety-Improving Features

Safety comes first in industrial applications. The BV89OEP-45 offers several features enhancing operational safety:

- Body and flange design that prevents blow-out under pressure

- Grounding of body, stem, and disc against static

- Fire-tested variants for use where high risks apply

- Manual overrides lockable to prevent misuse

Such safety features make the valve highly suitable for processes where personnel safety and environmental regulatory compliance are important considerations.

Economic Advantages of the BV89OEP-45

Lower Installation Costs

The BV89OEP-45’s in-line size and low weight yield significant installation advantages:

- Reduced piping support structure needed

- Ideal for space-limited installations

- Reduces hours of installation labor

- Compatible with industry standard flange sizes

These factors work to minimize up-front installation cost compared to other valve technologies.

Energy Efficiency

The flow path optimized of the BV89OEP-45 contributes to system efficiency:

- Reduced pressure drop implies reduced pumping energy requirements

- Proper throttling avoids wasted energy from over-pumping

- Lower operating torque demands reduce actuator energy consumption

- Tighter shutoff avoids costly leakage losses

Throughout the valve’s service life, these efficiency gains can translate into substantial energy cost savings.

Longer Service Life

Valves in industrial use are subjected to rough conditions that lead to premature failure. The durability properties of the BV89OEP-45 provide longer life:

- Hardened bearing surfaces resist wear

- Corrosion-resistant components maintain integrity in harsh environments

- Replaceable wear components lengthen total service life

- Strong disc-to-stem joints prevent failure at usual points

These life-prolonging benefits reduce the frequency of valve replacement and associated system downtime.

Environmental and Regulatory Compliance

Industrial processes today must meet increasingly stricter environmental regulations. The BV89OEP-45 helps plants remain compliant with:

- Low-emission packing solutions that equal or surpass fugitive emission requirements

- Bubble-tight shutdown that prevents product loss and environmental release

- Accommodation of VOC-compliant materials on all wetted surfaces

- Certifications for food-grade and drinking water are offered

These aspects of compliance defend facilities against regulation penalty threats while maintaining corporate sustainability programs.

Implementation Considerations

When purchasing the BV89OEP-45 for use in industry, several considerations are necessary:

Material Selection

The valve is available in many forms of materials to accommodate differing application requirements:

- Carbon steel construction for general industrial duty

- Stainless steel as one choice for corrosive duties

- Exotic alloys for chemical or high temperature exposure

- Disc, seat, and stem materials of various kinds to optimize performance for specific media

Material selection is key for maximum service life at lowest lifecycle cost.

Sizing Considerations

Proper valve sizing is crucial for optimum performance. Key considerations include:

- Maximum and minimum flow capacities

- Range of operating pressure

- Velocity constraints

- Control characteristics required (on/off vs. throttling)

Loss of control resolution due to excessive pressure drop and velocity-induced damage can result from undersized valves, while oversized valves will result in poor control resolution and high cost.

Automation Integration

In automated applications, the BV89OEP-45 is available with:

- Digital positioners to provide precise control

- Limit switches for feedback of position

- Network communication protocols (HART, Foundation Fieldbus, Profibus)

- Intelligent diagnostics for predictive maintenance

These automation functions allow the valve to be incorporated as a seamless element of high-control systems.

Conclusion

The BV89OEP-45 2-Way Butterfly Valve is a perfect blend of performance, dependability, and value for various industrial applications. Its advanced design features eliminate common problems involved with traditional valve technologies, and its flexibility addresses the various needs of modern industrial processes.

For plant managers and engineers who demand reliable flow control that maintains minimum maintenance requirements along with high performance levels of efficiency, the BV89OEP-45 provides an attractive collection of advantages. For corrosive chemicals, hot fluids, and abrasive slurries, this valve’s robust building and adaptability guarantee it the ideal valve in harsh industrial settings.

By employing the BV89OEP-45, industrial processes can enhance process dependability, reduce energy consumption, and reduce environmental footprint—while realizing long-term cost savings through reduced overall cost of ownership. In the competitive market for industrial valve technology, the BV89OEP-45 is an upgraded solution to modern industrial flow control requirements.

Recent Posts

- Ball Valve vs. Gate Valve: Understanding the Differences

- Actuated Ball Valves and Butterfly Valves Troubleshooting and Maintenance

- What Is a Cameron Type FLS Hydraulic Gate Valve and Why It’s Important for Frac Operations

- Why the BV89OEP-45 2-Way Butterfly Valve is Most Suitable for Industrial Application